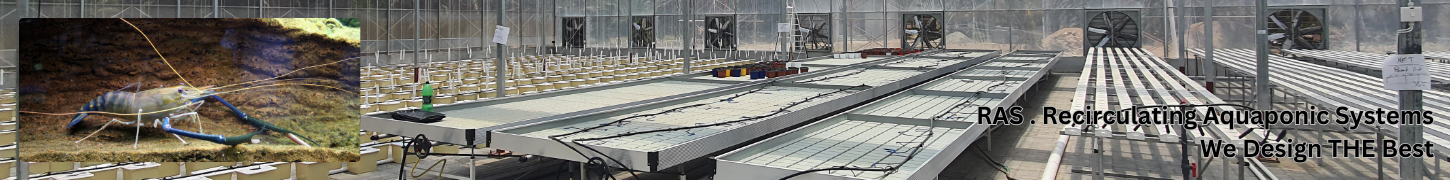

A key to successful RAS is the use of cost-effective water treatment system components.

Water treatment components must be designed to eliminate the adverse effects of waste

products . In recirculating tank systems, proper water quality is maintained by pumping tank water through special filtration and aeration and/or oxygenation equipment. Each component must be designed to work in conjunction with other components of the system. To provide a suitable environment for intensive fish production, recirculating systems must maintain uniform flow rates (water and air/oxygen), fixed water levels, and uninterrupted operation .

The excretion of TAN by the fish varies depending on the species in culture. As a general rule, when 1.0 mg of oxygen per litter per minute is consumed by the fish, the fish can produce 0.14 mg of TAN and specifically for salmonids species, per 1.0 mg of DO consumed per litter they can produce 0.04-0.06 mg of TAN per litter .

Biofilters contain both nitrifying bacteria and heterotrophic microorganisms that metabolize TAN and organic matter passing through the biofilter or entrapped within the biofilter. The net result of the biofilter microbial respiration are a decrease in TAN, biodegradable organics, dissolved oxygen, alkalinity, and pH, and an increase in oxidation products of organics, as well as, NO2-N, NO3-N, and CO2. Taking into account the overall stoichiometric relationship between subtracts and products produced during nitrification and nitrifier synthesis, nitrifying bacteria consume 4.6 mg L-1 of oxygen while producing approximately 5.9 mg L-1 of CO2 for every 1.0 mg L-1of TAN consumed and 1.38 mg L-1of CO2 are produced for every 1.0 mg L-1of dissolved oxygen consumed, when the respiration activity of nitrifying bacteria and heterotrophic microorganism are considered together.

Nitrate (NO3-N) is the end product of nitrification process. NO3-N is considered as the minimum toxic nitrogen product, with 96-h lethal concentration values more than 1000 mg (NO3-N L-1) for some aquaculture species. In recirculating systems, NO3-N levels are controlled by daily water exchanges,but in some systems with low water flow rate this parameter has become increasingly important and its concentration levels should be lower than 10 mg NO3-N L-1 .

Quality of water is more important important than Quantity

A biofilter is simply a device that provides a large amount of surface area for the nitrifying bacteria to grow When a new system is started up, the biofilter will not be active. Before stocking animals into the system, the biofilter will need to be conditioned. During the conditioning period an inorganic source of ammonia, such as ammonium chloride, is added to the system. A source of inorganic nitrite, such as sodium nitrite, can also be added to the system water to accelerate the conditioning process As the ammonia concentration falls, the nitrite concentration rises. The nitrite levels will peak and then begin to fall as the Nitrobacter population becomes established. Chronic overfeeding may lead to a buildup of uneaten feed in the culture tank and in sumps and filters. In addition to causing high ammonia levels, decomposing feed in a tank can serve as a substrate for Vibrio bacteria. These bacteria may infect and kill shrimp, especially if high ammonia levels have weakened the disease resistance of the shrimp. High ammonia levels may be indicative of a problem with the biofilter. The effectiveness of the biofilter can be determined by measuring the efficiency of the biofilter. Biofilter efficiency is a measure of the percentage of ammonia (or nitrite) removed by the biofilter in a single pass:

Biofilter Efficiency = [ ( TAN In – TAN Out ) / TAN In ] * 100%